Core-Leaching Autoclaves

NEW SYSTEMS FOR REMOVAL OF CERAMIC INSERTS CAUSTIC AUTOCLAVE

Core-Leaching Autoclaves

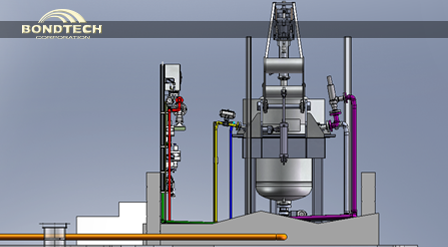

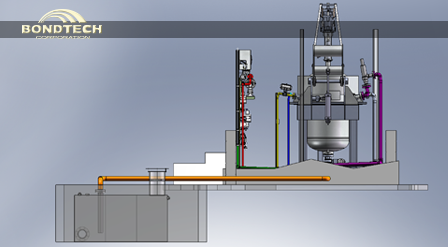

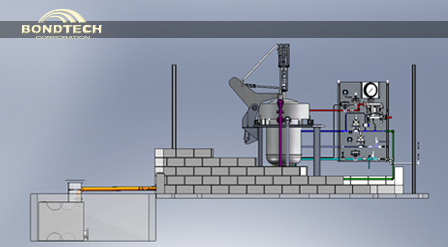

The Bondtech Core Leaching and removal system, is a self-contained high pressure, high temperature capable caustic autoclave system, utilized in the removal of ceramic inserts from high nickel alloy investment castings. Each system is custom designed for the application and the product processed

Downlod Autoclave Core-Leaching PDF brochure

-

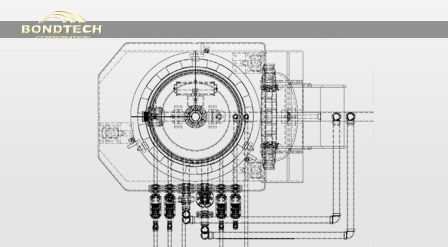

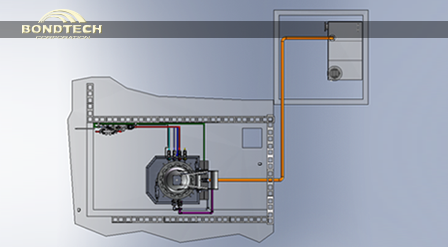

BONDTECH BCL31x36 (Typical System)

Chamber dimensions:

Vessel Size 31″IDx36″ Deep Autoclave Vessel Work Area 28″IDx28″ Deep Autoclave VesselVessel Construction:

The Bondtech Autoclave will be a heavy commercial grade autoclave. It will be designed and manufactured in strict accordance to the ASME and National Board of Boilers and Pressure Vessel Inspectors code. The Bondtech autoclave will be designed in accordance to your specifications and requirements. Corrosion resistant materials are used throughout the vessel to provide longevity and reliability during the systems life time.

- Door Specifications:

Bondtech has full access to the interior of the autoclave thru a Quick Opening Door. The door is a breech lock type door that does not produce any relative motion between the door and the pressure sealing o-ring. Bondtech’s door design operates by rotating the locking ring a few degrees to expose the door lugs through cut out areas of the lock ring. The door is then simply pivoted 90˚ to allow full access to the interior. The lock ring and door swing operation are interfaced to prevent operation when pressure of 1.5 PSI is present in the autoclave. The door safety includes an interlock. It complies with Section UG-35 of the ASME code. This will provide mechanical interlock to prevent opening of the door while under pressure.

Single and Double ‘O-Ring’ seals are available to seal the door based on the customer’s request. Water cooled double seals are utilized on all higher operating temperature and pressure systems to insure a tight leak proof closure.

- Heating and Insulation System:

The Bondtech heating and insulation system is properly sized to meet the design temperature requirements:- UN Zoned band type heaters with SCR control

- Multiple zones independently controlled

- Interlocked with the fill and drain of the vessel

- Easy to service siliconized insulation blankets.

- Each zone is individually power fused to provide high reliability and safety.

Temperature Monitoring Devices:

- Thermocouple Type K on each zone for heater over temperature

- Thermocouples Type K for internal vessel process temperature control

- Exterior:

- Non corrosion resistant material surfaces

- Painted with heat and corrosion resistant primer and paint

Chamber Pressure:

- Chamber pressure transducer

- Actuated chamber pressure valves

- Compressed air or nitrogen provided by customer

- Basket and System Agitation:

- A heavy duty corrosion resistant basket for holding working parts for processing.

- A positive engagement latch system to remove the operator involvement in attaching the basket to the agitator

- Automated agitation is set by the control system

- Vertical agitation of the loaded basket is available for processes requiring the movement of the charged caustic to clean the surfaces.

- Agitation rates and dwell times are programmable

- Systems can be purchased without agitation

- Requires no operator action to interface the basket to the agitator

- Safety Valves, Attachments and Alarms:

- Cycle drain active alarm

- Drain Quench tank over-temperature alarm

- Vessel over-temperature and over-pressure alarm

- Safety relief and Rupture disk

- Pressure switch for high and low pressure alarm

- Door position limit switches

- Cycle drain active alarm

- Drain Quench tank over-temperature alarm

- Vessel over-temperature and over-pressure alarm

-

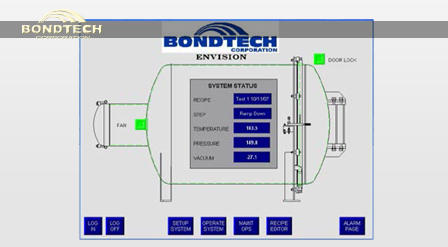

Controls

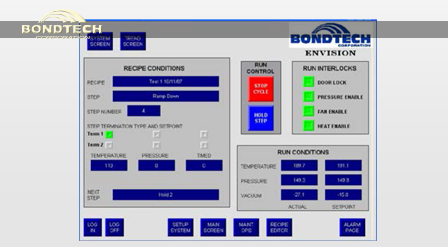

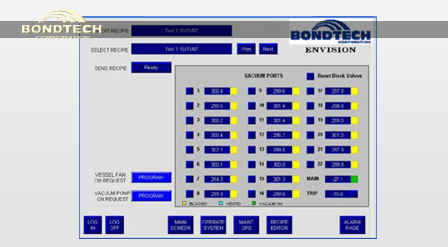

Allen Bradley CompactLogix PLC programmable control system including system to download data for autoclave control with the following features:

- Control heating ambient to 900˚F.

- Run at precise temperatures for programmed time period from a type K thermocouple inputs

- Run at precise pressures for programmed time period from a transducer input

- Aautomatic control of cycle sequences from start to end

- Operator controls for locking and unlocking door

- Process complete and ready to open door indicator lights

- Temperature and pressure safety back-ups

- Full program editing and storage capabilities

- On/off control of pressure from transducer

- On/off control of caustic transfer pump

-

Control features

- Utilizes a “State of the Art” Multi-tasking PLC processor

- Programmed using IEC compliant programming software

- The PLC system is completely industrially hardened

- Industry standard Allen Bradley components

- Industrial grade IO with built in opto-isolation

- Standard IO interface types are used throughout the system 24VDC, 120VAC, 4-20mA, 0-10VDC, and ISO type TC inputs.

- PLC programming contains a true ‘Logic Engine’ to determine the step to step transitions.

- Completed profile data download capabilities

- Multiple process conditions can be evaluated to satisfy the step change criteria

-

- The controlling point is conditional can be changed with each step change, whether it the Leading Part TC, the Lagging Part TC, Average of the Part TC’s, or the Vessel TC, the Process Engineer decides, which to use when. • Temperature control loops are Fuzzy Logic capable and can be set for

single loop or cascade loop control for running off the Part TC’s. - Bondtech PLC based systems typically show temperature control of better than +/- 1˚ F during heat soak periods and +/- 3˚F during ramping. Refit system will be existing quipment dependent.

- Bondtech PLC based systems typically show pressure control of better than +/- 0.5 PSI. Refit system will be existing equipment dependent.

- The controlling point is conditional can be changed with each step change, whether it the Leading Part TC, the Lagging Part TC, Average of the Part TC’s, or the Vessel TC, the Process Engineer decides, which to use when. • Temperature control loops are Fuzzy Logic capable and can be set for

-

- Bondtech systems utilize industrially hardened PCs running Windows 7 Professional software for Operator Interface and Data Acquisition. The PLC runs independent of the PC, and can complete the process to specification without the PC being available. • The Bondtech EnVision software is multi-level security enabled, to prevent un-authorized changes to ‘recipes’ and operation.

- The operator is guided through the system, with a dedicated setup page, and a detailed operation page. This simplifies the process to load and start a run, so there are no missed steps.

- Simple one button startup, the autoclave PLC handles the rest.

- Automated Data acquisition by the EnVision system, with strip chart like graphing of standard running variables.

Downlod Autoclave Core-Leaching PDF brochure

Design Features

Bondtech is a sole supplier of new and refurbished autoclaves and pressure vessels. The single source capability represents direct control starting with coordinated mechanical and metallurgical design through the final test of the complete system.

When reconditioning an existing system, Bondtech uses the most advanced technology to bring the autoclave up to today’s standards. When the autoclave is completed, the unit will not only look like new, but it will also perform and last like a new unit. When refurbishing a unit, we will take into consideration our customer’s unique requirements as well as budget considerations.

-

Bondtech’s Advantages:

-

- State-of-the-art

- Cost Savings

- Custom Design

- Modifications and Repairs

-

- Immediate Response and Service

- Shorter Manufacturing Leadtime

- Single Source

- High Quality