Bondtech Additional Qualifications

Bondtech is not “just another machine shop.” We are a manufacturing support and tooling service company who puts the strongest emphasis on Quality, Value, and Delivery.

We have invested in the latest available technology in CNC Machines, CAD/CAM Software, and Reverse Engineering Equipment allowing us to meet the needs of our Aluminum Die Casting, Stamping, and Plastic Molding Customers. We have also invested in highly skilled personnel and testing equipment to maintain the highest standards.

-

CNC machining

CNC (Computer Numerical Control) machining allows fast, repeatable and programmable machining to extremely close tolerances. Our state of the art machining equipment networked with our in-house CAD engineering department provides for an efficient and quality controlled workflow. CNC capability allows us to produce extremely complex shapes.

For CNC programming, Bondtech is currently operating six seats of Tebis and four seats of Surfcam three axes plus programming and design software. We program all our own machines as well as offering a custom programming service with the ability to post to almost any machine control including mills, lathes, and wire EDM.

Bondtech has many high performance machines to produce your part including vertical and horizontal CNC Mills, Wire EDM, and CNC Lathes. We have made investments in the highest quality

-

Conventional machining

In addition to our high technology CNC equipment, Bondtech has a large array of conventional machining equipment and capabilities.

We also offer:- TIG / MIG, Stick and oxygen / acetylene welding

- cutting

- grinding

- heat treat

- repair

- assembly services

-

Engineering

- Reverse Engineering

- Tebis V 3.2 CAD with reverse Engineering capabilities

- Tebis V 3.2 CAM Programming Software

- Surfcam 2000

- AutoCAD Mechanical desktop 2006

-

Reverse Engineering

No CAD? No Prints? No Problem!Bondtech utilizes dimensional scanners to gather two-dimensional and thee-dimensional information about a part. The digital information from our scan of a part is fed directly to our CAD engineering systems, which can then feed directly to our CNC machining equipment to produce an exact replica of the original part. Once in our CAD department, the part specifications can also be modified and updated to make an improvement upon the original.

-

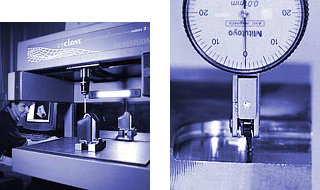

Bondtech Quality

Our quality is controlled by our full time Quality Assurance Manager and the enforcement of strict quality procedures. Each part produced at Bondtech is inspected for quality assurance. We take great pride in our quality control system. To aid in this we have the Brown and Sharpe Global CMM and the Renishaw Cyclone Series 2 2D/3D Scanner as well as various other inspection equipment.

It is our policy to continually strive for manufacturing excellence, ensuring our customers consistently receive a superior mix of quality, delivery, and price. By the use of quality control reports and our digitally networked workflow, we can accurately keep track of quality checks while maintaining a smooth work flow.But most importantly, we continue to build our business, and our reputation, on the consistently high quality of our work.

-

Customer Service

Bondtech has made substantial investments in the latest high-technology equipment to accommodate the most demanding machining needs. To see a list of our equipment click on the link below.

Equipped for service

At Bondtech Machine Service we don’t only talk about customer service. We strive to build our business around it. This Data base is another one of the ways we have developed to better serve all of our customers. We now have the ability to database information about all the items you purchase whether we are the source for these items or not.

Through this system you will be able to access information from anywhere in the world with access to the internet. Not only will your information be stored in a database but all engineering changes can be communicated through this system and the information promptly updated for future reference. What we offer is a program that benefits you as a customer in many ways.